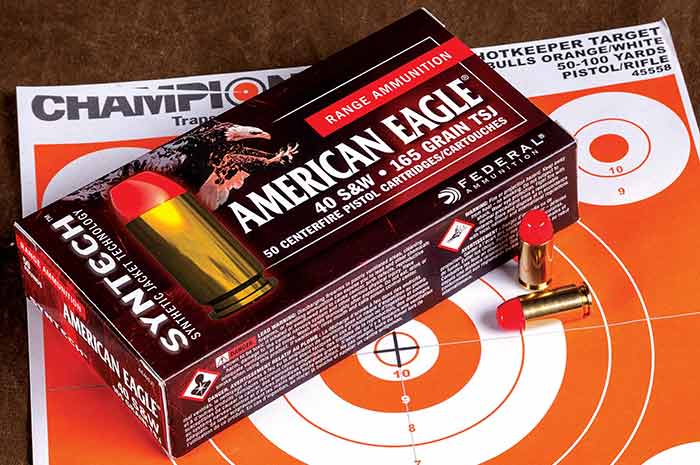

Federal Premium will introduce a new line of ammunition under its American Eagle brand at the SHOT Show. Called Syntech, the new ammunition uses a polymer jacket instead of a more traditional copper one.

The new ammo will be offered in three handgun calibers at launch: 9mm, .40 S&W and .45 ACP. Bullet weights will be typical for the caliber: 115 grains for the 9mm, 165 grains for the .40 and 230 grains for the .45.

Using a polymer jacket has a number of potential advantages for the company and the shooter. First, Federal may be able to manufacture these bullets for less money than if the company used a traditional copper jacket. This can work out to be lower prices for the consumer.

Secondly, by using a polymer jacket, there can be less fouling of the bore. Plain lead bullets can leave quite a bit of residue behind that is tough to scrub out. Copper jackets reduce the fouling, but copper is still tough to remove from a bore. Any polymer left behind is likely to be easier to remove from the pistol’s barrel.

Another potential benefit of using a polymer jacket is a reduction in “splash back” when shooting steel. Shooting steel targets is both fun and useful as a training tool. However, one of the risks involved bullet shrapnel bouncing back at the shooter. Even when operating at supposedly safe distances, I’ve seen part of a copper jacket come back and strike a shooter just above the eye. In theory, a polymer jacket will not rebound off of steel in the same way that copper would.

American Eagle Syntech ammunition is not the first time the company has used a polymer jacket. Federal used a polymer jacket on its popular Nyclad line of ammo many moons ago, and still does on the modern Nyclad .38 Special rounds.

For these loads, Federal used a soft lead alloy that would readily expand at even low velocities. However, copper jackets would inhibit expansion, and bare lead would leave a lot of gunk behind in the gun. To solve the problem, a polymer jacket was developed.

While the Nyclad line was eclipsed by other defensive ammunition lines, I am not familiar with any problems with the ammo caused by the polymer jacket.

I do not have any word on pricing yet for these rounds. As I get additional information leading into the SHOT Show, I will update this article.

7 replies on “American Eagle Syntech Ammunition”

So they have taken what cast bullet shooters have been doing for years “powder coating” and saying they invented it?

They may be the first to sell it as manufacturered ammo. But credit belongs to the home casters that have devopled and tested this method.

I’m glad to see it on the market. But I’ll still cast my own

Search powder coated bullets in http://www.castboolits.com

Not just that, but Herter’s has been doing it for a while now with their cheap aluminum cased ammo.

I don’t claim to know everything about loading, as I only got into it during the late 90’s and have been a bit slack in pulling the handle in recent years. So, I’m not sure when folks started handloading coated bullets.

However, if memory serves, Smith & Wesson began loading the Nyclad line in the 70’s after they purchased the Alcan brand. After a few years, the Nyclad brand/technology was purchased by Federal who expanded the line. Somewhere in the 90’s the company shut down the line for lack of sales. Then in recent years, Federal returned the Nyclad .38 Spl 125 gr HP to production as a standard pressure defensive load for J-frames and the like.

I presume that this is an extension of the company’s Nyclad manufacturing history, and essentially a return to where S&W first started the line – as a non-HP bullet that acts as a TMJ (for lead purposes anyway) at a less cost than copper.

Like a lot of innovations, I would not be surprised to discover that someone working on his bench came up with the concept in the 60’s (or whenever) and later Alcan/S&W figured out how to do it on a larger scale.

Like you, I’m glad to see it on the market. More options is more better. Especially for those of us who don’t pull the handle as often as we would like.

-Richard

Yes. I was doing some more reasrach on it myslelf as well.

Altnerate coating’s have been played with and tested for decades.

Nyclad is a nylon coating. This is a polymer plastic.

Tons of load data and test results for pc.

Nylon is a polymer, and the Nyclad coating process was a form of powder coating.

Here’s the original S&W Nyclad patent. (Bangor Punta owned S&W back in those days.)

https://www.google.com/patents/US4328750

Thanks for the link Daniel!

“A rose by any other name would smell as sweet”, in this case powder coating would shoot just the same. Glad I can make my own.